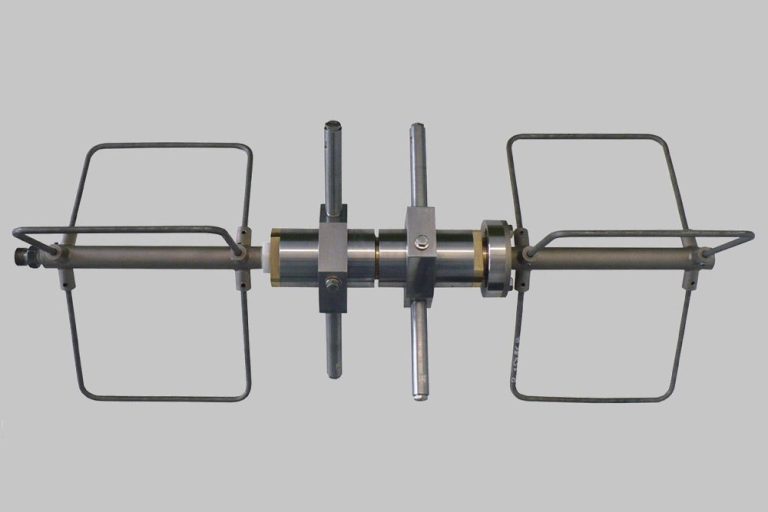

Well Cleaning Nozzle

Well regeneration best by cleaning with high-pressure water jetting

Self-rotating well cleaning nozzle cleans efficiently together with high-pressure water jet

The regular cleaning and regeneration of deep water wells is essential for the water quality and the flow. The best regeneration option is to clean the well using water at high pressure and using a specially developed well cleaning nozzle. This well cleaning nozzle cleans both, the inner walls of the pipes as well as the filter slots, and, generates turbulence in the filter gravel bed which is responsible for separating the deposits in the filter gravel.

Shaft sealing in front of the well cleaning nozzle’s housings prevents the ingress of dirt particles

The KAMAT Well Cleaning Nozzle is placed over the well by means of a support (e.g. a frame, etc.) and hanging on the hp hose (including a safety line, not supplied). By means of a special shaft sealing in front of the nozzle housings, penetration of sand and similar dirt particles during operation in the filled well is not possible. A jamming of the rotating nozzle housing on the shaft is thus excluded, as opposed to a pure pipe / sewer flushing nozzle.

Special sealing system guarantees tightness of the cleaning nozzle during operation

The nozzle consists of two counter-rotating nozzle housings, into which the nozzle pipes with connection for round jet screw-in nozzles are inserted. A special packing sealing system inside the nozzle housings ensures the protection during operation and prevents the penetration of impurities. In front and behind of the nozzle housings are so-called spacers (basket system), which prevent that the nozzle pipes are not hitting against the well wall. Next to this, for best cleaning results, the medium’s temperature should be between 3 and 30 °C.

Technical Specifications

- max. working pressure: 500 bar

- max. flow rate: 200 l/min

- hp connection: M 22×1.5 DKL

(other pressure nipples on request) - min. pipe (well) Ø 140 mm

- max. quantity of nozzles: 4

- threaded nozzles form S G 1/4“

- length total ~ 870 mm

- weight ~ 21.0 kg

- without set of nozzle tube (4pc.)

and distance holder (6pc.)

Special Features

- easy handling

- additional screw-in nozzles available

- self-rotating

- no penetration of impurities possible

- no settling due to contamination possible

- basket system

Additional Literature

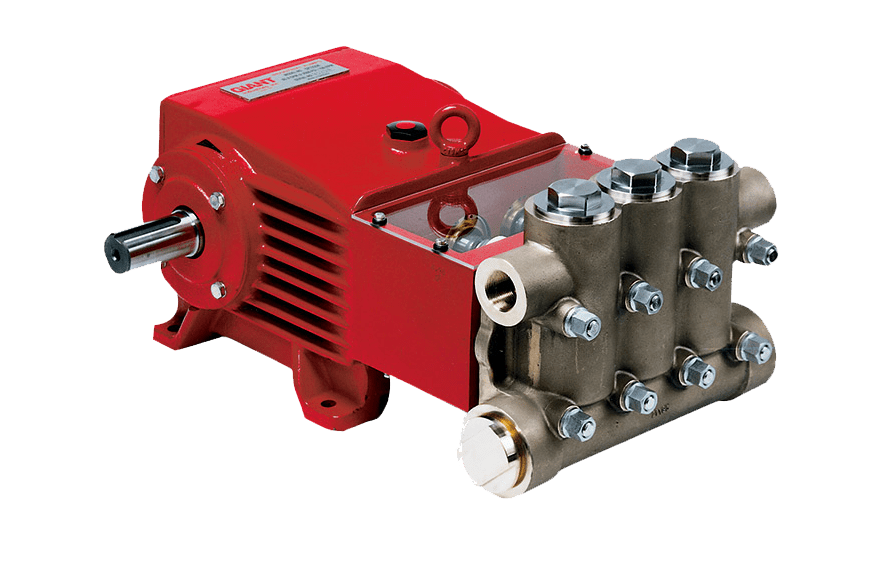

Our Company

For 50 years, Giant Pumps has offered the most dependable positive displacement high-pressure triplex pumps available. Designed and built to the highest quality standards, customers count on Giant Pumps products to keep their equipment running. Every design detail of Giant Pumps products is optimized for long-life and reliable performance, making Giant Pumps the most trusted name in high-pressure pumps and systems.