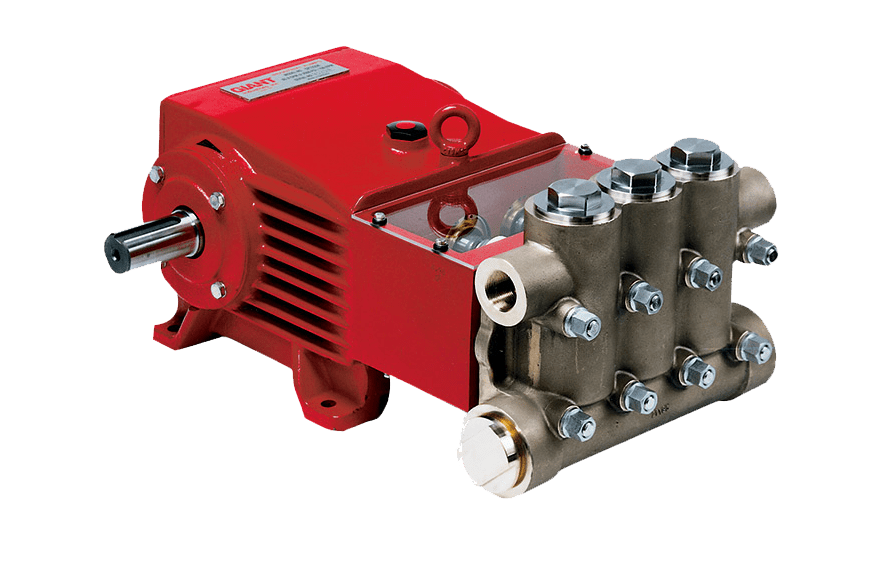

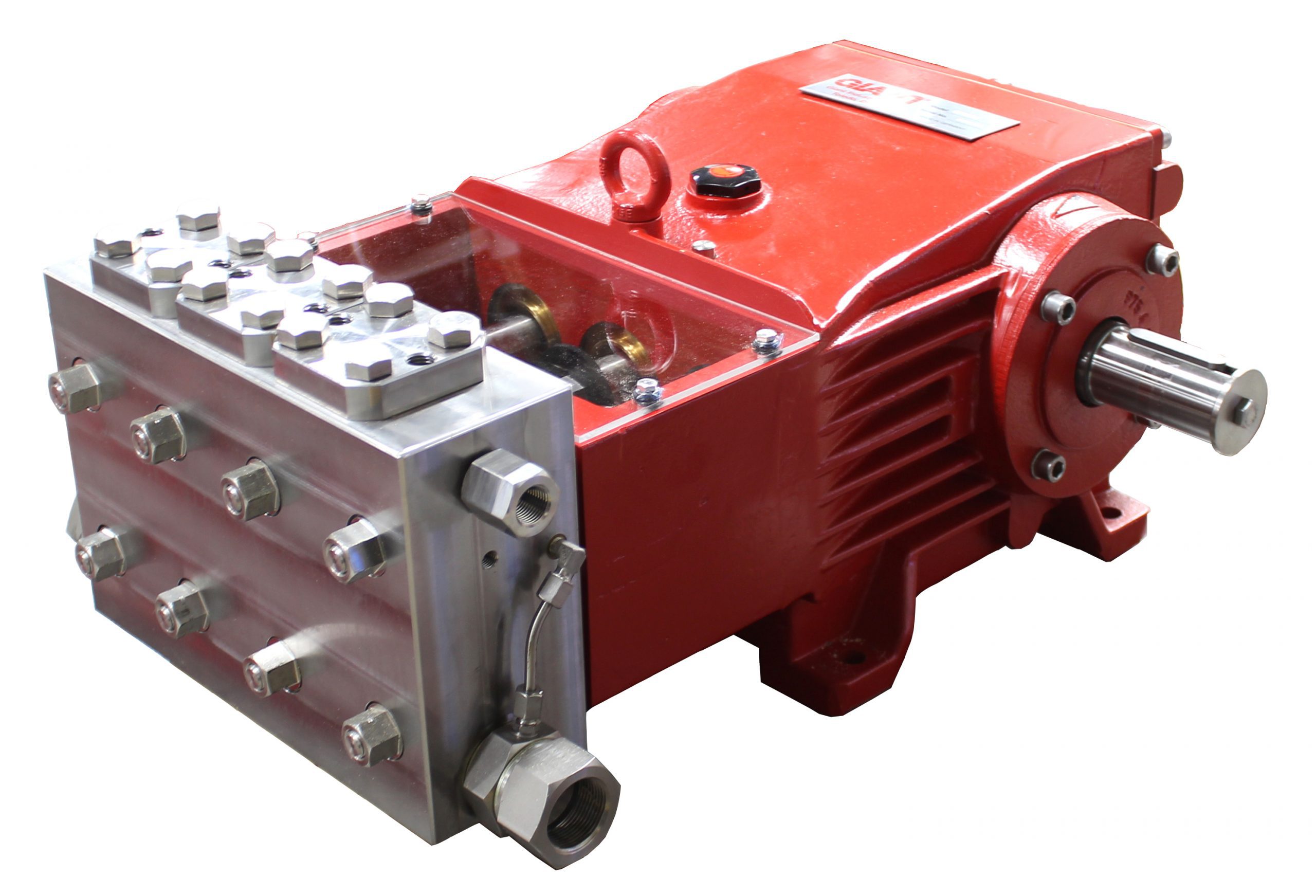

GP7124A-4000

A German-made reciprocating triplex plunger pump.

Features:

Spheroidal cast iron crankcase with vented dipstick; forged, through-hardened, ground and polished crankshaft; bronze connecting rods; hardened stainless steel plunger bases; stainless plungers with hardened metal coating; aramid packing; stainless steel valves and machined stainless steel manifold.

WARNING: This product might contain a chemical known to the State of California to cause cancer, and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

| Specification | US | Metric |

|---|---|---|

| Flow | 12.8 GPM | 48.4 L/min |

| Maximum Discharge Pressure | 7400 PSI | 510 bar |

| Crankshaft Speed | 750 RPM | |

| Power | 65.3 HP | 48.7 KW |

| Max Temperature | 140 °F | 60 °C |

| Inlet Port Size | (2) 1-1/4" NPT | |

| Discharge Port Size | (2) 3/4" NPT | |

| Plunger Diameter | 0.94 in. | 24 mm |

| Stroke | 2.05 in. | 52 mm |

| Maximum Inlet Pressure | 58 PSI | 4 bar |

| Crankshaft Diameter | 1.9 in. | 48 mm |

| Crankshaft Rotation | Top of Pulley Towards Manifold | |

| Key Width | 0.55 in. | 14 mm |

| Crankshaft Mounting | Either Side | |

| Crankcase Oil Capacity US | 1.7 gal | 6.5 L |

| Weight | 454 lbs. | 206 kg |

| Volumetric Efficiency | 89 | |

| Mechanical Efficiency | 83 | |

| Manifold Material | Machined Stainless Steel | |

| Crankcase Material | Spheroidal Cast Iron | |

| Plunger Material | Stainless Steel with Hardened Metal Coating | |

| Valve Material | Stainless Steel | |

| Seal Material | Aramid Packing |

| ITEM# | PART# | DESCRIPTION | Qty. |

|---|---|---|---|

| Plunger Packing Kit – Part #09224A | |||

| 38B | 06750 | Leakage Gasket | 3 |

| 38C | 06667 | O-Ring | 3 |

| 39A | 07150 | O-Ring | 6 |

| 42 | 07685 | Packing | 6 |

| 43 | 07718 | Support Ring | 6 |

| 44 | 06956 | Guide Ring | 3 |

| 46 | 07169 | Seal Ring | 3 |

| 48 | 05524 | Circlip | 3 |

| Inlet Valve Assembly Kit – Part #09702 | |||

| 51B | 05193 | O-Ring | 3 |

| 51C | 05194 | Inlet Valve Seat | 3 |

| 51D | 06761 | Valve Plate | 3 |

| 51E | 06762 | Valve Spring | 3 |

| 58A | 07700 | O-Ring | 3 |

| 58B | 07693 | Support Ring | 3 |

| Discharge Valve Assembly Kit – Part #09703 | |||

| 52B | 05193 | O-Ring | 3 |

| 52D | 06761 | Valve Plate | 3 |

| 52E | 06762 | Valve Spring | 3 |

| 52C | 05195 | Discharge Valve Seat | 3 |

| 58A | 07700 | O-Ring | 3 |

| 58B | 07693 | Support Ring | 3 |

| Oil Seal Kit – Part #09221 | |||

| 32 | 07624 | Radial Shaft Seal | 3 |

| 33A | 07627 | O-Ring | 3 |

Horsepower Specifications

| RPM | GPM | 5000 PSI | 6000 PSI | 7000 PSI | 7400 PSI |

|---|---|---|---|---|---|

| 400 | 6.8 | 23.5 | 28.3 | 32.8 | 34.7 |

| 550 | 9.4 | 32.4 | 38.9 | 45.4 | 48.0 |

| 600 | 10.2 | 35.2 | 42.2 | 49.2 | 52.1 |

| 650 | 11.1 | 38.3 | 45.9 | 53.6 | 56.7 |

| 700 | 12.0 | 41.4 | 49.7 | 57.9 | 61.2 |

| 750 | 12.8 | 44.1 | 53.0 | 61.8 | 65.3 |

Images Open in new Window/Tab

Literature

Documents open in new window/tab.

Our Company

For 50 years, Giant Pumps has offered the most dependable positive displacement high-pressure triplex pumps available. Designed and built to the highest quality standards, customers count on Giant Pumps products to keep their equipment running. Every design detail of Giant Pumps products is optimized for long-life and reliable performance, making Giant Pumps the most trusted name in high-pressure pumps and systems.